The recent escalation in BMW emissions has precipitated widespread concern amongst vehicle proprietors and environmental advocates. A profound comprehension of the emission control systems inherent within BMW automobiles is imperative for tackling this predicament.

The imperative for efficacious emission control cannot be overstated, given its direct correlation with mitigating the ecological footprint of motorized transport. This compendium delves extensively into the emission control systems of BMWs, proffering actionable advice on the upkeep of your vehicle to curtail its emissions.

Key Takeaways

- Understanding BMW emission control systems is key to reducing emissions.

- Regular maintenance can significantly lower emissions from BMW vehicles.

- Diagnostic tools play a crucial role in identifying emission-related issues.

- Proper tuning and servicing can help maintain optimal emission levels.

- BMW owners can contribute to a cleaner environment by following emission-reducing tips.

Understanding BMW Emissions Systems

The role of emission control systems in BMW vehicles is paramount in mitigating their environmental impact. An in-depth exploration of their components and operational mechanisms is imperative for comprehension.

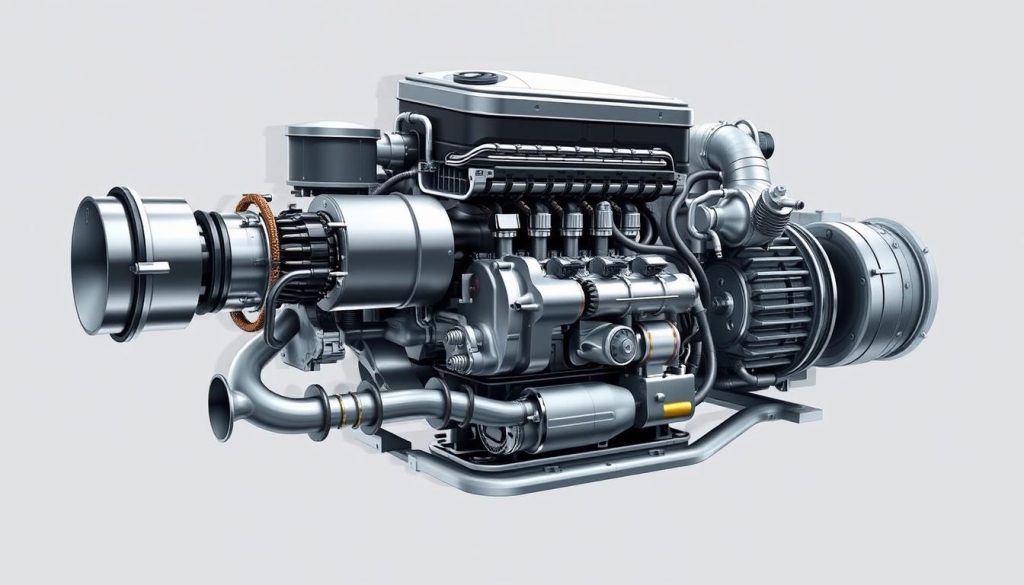

How BMW Emission Control Systems Work

BMW’s emission control systems are advanced technologies aimed at curtailing harmful emissions. These systems differ between gasoline and diesel models, each boasting distinct components and functionalities.

Primary Emission Control Components

The core components comprise oxygen sensors and catalytic converters, collaborating to diminish emissions. Oxygen sensors track exhaust gas oxygen levels, while catalytic converters leverage this data to refine the exhaust process.

Differences Between Gasoline and Diesel BMW Systems

Divergence exists between gasoline and diesel BMW models in their emission control systems. Diesel models, for example, incorporate additional components such as diesel particulate filters to mitigate soot emissions.

Key Components in BMW Emission Systems

Essential components also include the exhaust gas recirculation (EGR) system and fuel injection systems. The EGR system is instrumental in curtailing nitrogen oxide emissions, whereas the fuel injection system optimizes fuel combustion.

| Component | Function | BMW Model |

|---|---|---|

| Oxygen Sensors | Monitor oxygen levels in exhaust gases | Gasoline, Diesel |

| Catalytic Converters | Reduce harmful emissions | Gasoline, Diesel |

| Diesel Particulate Filters | Reduce soot emissions | Diesel |

Emission Standards for BMW Vehicles in the US

BMW must adhere to EPA requirements, which are subject to federal and California regulations. Grasping these standards is critical for maintaining regulatory compliance.

Current EPA Requirements

The EPA mandates stringent emission standards for vehicles in the US. BMW models must fulfill these standards to be eligible for sale in the American market.

California vs. Federal Standards

California’s emission standards are more stringent than federal regulations. BMW models destined for California must adhere to these stricter standards.

Increased Emissions from BMW: Causes and Potential Solutions

Grasping the underlying causes of elevated emissions in BMWs is imperative for devising effective countermeasures. Emission surges can stem from a multitude of factors, encompassing mechanical component failures and electronic system malfunctions.

Common Causes of Emission Spikes

Several elements contribute to heightened emissions in BMWs. Mechanical component failures are a pivotal factor.

Mechanical Component Failures

Defective oxygen sensors, obstructed fuel injectors, and malfunctioning catalytic converters are prevalent mechanical issues precipitating emission surges. Proactive maintenance is instrumental in averting these maladies.

Electronic System Malfunctions

Electronic malfunctions, encompassing issues with the Engine Control Unit (ECU) or faulty sensors, also induce elevated emissions. Diagnostic tools are indispensable for pinpointing these problems.

Warning Signs of Emission Problems

Identifying the warning signs of emission-related issues is crucial for BMW owners to address problems promptly. Dashboard warning lights serve as a primary indicator.

Dashboard Warning Lights

The check engine light is a quintessential indicator of emission-related malfunctions. It signifies that the vehicle’s onboard diagnostics system has detected an anomaly.

Performance Changes and Symptoms

Alterations in vehicle performance, such as diminished fuel efficiency or erratic idling, are indicative of emission-related issues.

Initial Assessment Steps

Confronted with emission issues, BMW owners should adhere to fundamental troubleshooting procedures to pinpoint the cause.

Basic Troubleshooting Procedures

Employing OBD-II diagnostic tools facilitates the identification of emission-related problems. These tools yield error codes that correspond to specific malfunctions.

Tools Needed for Diagnosis

An inventory of necessary tools encompasses OBD-II scanners, multimeters, and fuel pressure test kits. Possessing the appropriate tools is essential for precise diagnosis.

| Tool | Purpose |

|---|---|

| OBD-II Scanner | Reading error codes |

| Multimeter | Checking electrical circuits |

| Fuel Pressure Test Kit | Testing fuel system pressure |

“Regular maintenance is paramount in preventing emission issues in BMW vehicles. By diligently adhering to routine checks and addressing problems expeditiously, owners can ensure their vehicles operate efficiently and sustainably.”

Diagnosing Emission Problems in BMW Vehicles

Accurate diagnosis of emission issues in BMW vehicles necessitates the selection of appropriate diagnostic equipment. OBD-II diagnostic tools are indispensable for identifying such problems.

Using OBD-II Diagnostic Tools

To effectively diagnose emission problems, one must first choose a BMW-compatible scanner. This entails understanding the various types of OBD-II scanners and their compatibility with BMW vehicles.

BMW-Compatible Scanner Selection

When selecting a scanner, it is crucial to opt for one that supports BMW-specific protocols. This ensures effective communication with the vehicle’s onboard computer.

Connecting and Reading Data

After selecting the appropriate scanner, the next step is to connect it to the vehicle’s OBD-II port and read the data. This process requires adherence to the manufacturer’s instructions for the scanner and comprehension of the data it provides.

Interpreting BMW-Specific Error Codes

Following data retrieval from the scanner, the subsequent step is to interpret the error codes. BMW-specific codes offer valuable insights into the nature of the emission problem.

Common Emission-Related Codes

Certain error codes are commonly associated with emission issues, such as those related to the catalytic converter or oxygen sensor. Understanding these codes is essential for accurate diagnosis.

Translating Codes to Specific Issues

The error codes must be translated into actionable diagnoses. This involves correlating the codes with specific components or systems within the vehicle.

Visual Inspection Techniques

In addition to using diagnostic tools, visual inspections play a critical role in diagnosing emission problems. This includes checking for vacuum leaks and inspecting exhaust components.

Checking for Vacuum Leaks

A visual inspection for vacuum leaks involves examining the vacuum hoses and connections for signs of damage or deterioration.

Inspecting Exhaust Components

The exhaust system should be inspected for damaged or corroded components, as these can significantly impact emissions.

Addressing Oxygen Sensor Failures

The imperative of addressing oxygen sensor failures cannot be overstated, as it directly impacts BMW performance and environmental stewardship. These sensors are instrumental in monitoring the air-fuel mixture, thus ensuring the engine’s efficiency and the regulation of emissions.

Identifying Faulty O2 Sensors

Malfunctioning oxygen sensors precipitate significant emission surges and a decline in fuel efficiency. The manifestation of such issues includes diminished performance and the activation of the check engine light.

Symptoms of Sensor Degradation

- Decreased fuel efficiency

- Performance issues

- Check engine light illumination

Testing Sensor Performance

Utilizing a scan tool to monitor the sensor’s voltage output is essential for testing. A sensor in disrepair will exhibit erratic or constant voltage readings.

Step-by-Step Sensor Replacement Guide

The process of replacing an oxygen sensor necessitates meticulous attention to detail. It is imperative to procure the correct replacement part and adhere to the manufacturer’s guidelines.

Tools and Parts Required

- New oxygen sensor

- Socket wrench or O2 sensor socket

- Anti-seize compound

Removal and Installation Process

The removal of the old sensor must be executed with precision, noting the wiring and its position. The installation of the new sensor should involve the application of anti-seize compound to the threads.

Post-Replacement Testing

Post-installation, it is crucial to clear any error codes and confirm the sensor’s functionality.

Clearing Error Codes

Employ a scan tool to eliminate error codes associated with the oxygen sensor. This action will reset the check engine light.

Verifying Proper Operation

Subsequent to the replacement, the vehicle’s performance should be closely monitored, and the recurrence of the check engine light should be checked. A sensor functioning optimally will ensure smooth engine operation and optimal emissions.

Resolving Catalytic Converter Issues

A malfunctioning catalytic converter can precipitate a multitude of problems, ranging from elevated emissions to diminished engine efficacy in BMWs. This critical component of a vehicle’s emission control system is tasked with the reduction of harmful pollutants. Its failure necessitates immediate attention to mitigate further damage.

Signs of Catalytic Converter Failure

Recognizing the indicators of a failing catalytic converter is paramount for prompt intervention. These indicators can be segmented into performance symptoms and diagnostic confirmation methodologies.

Performance Symptoms

The performance symptoms indicative of a failing catalytic converter encompass:

- Decreased engine potency and performance

- Augmented fuel consumption

- A rough idle or hesitation during acceleration

Diagnostic Confirmation Methods

Diagnostic tools and methodologies are employed to confirm catalytic converter failure. These include:

- Utilizing OBD-II scanners to identify specific trouble codes related to the catalytic converter

- Conducting a visual inspection for signs of damage or clogging

- Executing a backpressure test to assess the converter’s condition

Cleaning vs. Replacement Options

The decision to clean or replace a faulty catalytic converter hinges on various factors.

When Cleaning Might Work

Cleaning the catalytic converter may be feasible if the issue stems from minor clogging or contamination. Yet, this approach is not universally effective.

When Replacement Is Necessary

Replacement is often imperative when the catalytic converter is damaged, clogged beyond repair, or has reached the end of its lifespan. Employing a high-quality replacement part is crucial for restoring performance and reducing emissions.

Selecting the Right Replacement Parts

Choosing the appropriate replacement catalytic converter necessitates consideration of OEM vs. aftermarket options and adherence to best practices for installation.

OEM vs. Aftermarket Considerations

OEM parts guarantee compatibility and performance, while aftermarket parts may offer cost savings but vary in quality. It is essential to weigh the pros and cons based on your specific needs and budget.

Installation Best Practices

Proper installation of a new catalytic converter entails ensuring correct fitment, securely tightening all connections, and conducting a post-installation check for leaks or damage.

Fixing EGR System Problems

The Exhaust Gas Recirculation (EGR) system is paramount for emission reduction in BMW vehicles, necessitating prompt resolution of its malfunctions to preserve engine efficacy. A dysfunctional EGR system precipitates elevated emissions, diminished fuel efficiency, and potential damage to other engine components.

EGR Valve Cleaning Procedure

The EGR valve’s cleaning is a pivotal step in addressing EGR system malfunctions. This entails the removal of the valve followed by the application of suitable cleaning methodologies to reinstate its operational integrity.

Removing the EGR Valve

The initial step in cleaning the EGR valve involves its removal. This process necessitates the disconnection of the electrical connector and any vacuum lines, accompanied by the unscrewing of mounting bolts to liberate the valve from its fixed position.

Cleaning Methods and Materials

Post-removal, the EGR valve is subjected to cleaning with a specialized cleaning solution. It is imperative to employ a product formulated for EGR valve cleaning to avert damage to the component. Soak the valve in the solution, then employ a soft brush to delicately dislodge any carbon deposits.

Replacing EGR Components

In scenarios where cleaning proves ineffective or the EGR components are irreparably damaged, replacement becomes imperative. This entails the identification and installation of the appropriate replacement parts.

Identifying the Correct Parts

To undertake EGR component replacement, it is crucial to identify the correct parts for your BMW model. Consultation with your owner’s manual or direct contact with a BMW dealership is recommended to ascertain the requisite components.

Installation Steps

The installation process mirrors the removal procedure. It is essential to ensure all connections are secure and the new components are correctly seated and fastened. Adherence to the manufacturer’s instructions is paramount for specific installation requirements.

Verifying Proper EGR Operation

Post-cleaning or replacement of EGR components, verification of the system’s proper functioning is imperative.

Testing EGR Function

Utilization of diagnostic tools to monitor the EGR system’s performance is advisable. Examination for any error codes related to the EGR system and confirmation of the valve’s proper functioning is essential.

Monitoring Performance After Repair

Post-repair, continuous monitoring of your vehicle’s performance and emissions is crucial. Persistent issues necessitate further diagnostic endeavors.

- Inspect for signs of EGR system failure, such as increased emissions or engine knocking.

- Employ diagnostic tools to monitor EGR system performance.

- Seek professional assistance if uncertain about any repair aspect.

Addressing Fuel System Related Emission Issues

The maintenance of a fuel system is paramount for the reduction of emissions in BMW vehicles. Issues such as clogged fuel injectors and malfunctioning fuel pressure regulators can significantly elevate emissions. Regular upkeep and the utilization of appropriate fuel are imperative in addressing these concerns.

Fuel Injector Maintenance

Fuel injectors are pivotal in the delivery of fuel to the engine, ensuring optimal performance. Their clogging over time can result in diminished engine efficiency and heightened emissions.

Cleaning Clogged Injectors

The process of cleaning clogged fuel injectors necessitates the use of specialized cleaning solutions. This entails circulating the solution through the fuel system to eradicate deposits and debris.

Testing Injector Performance

Post-cleaning, it is imperative to test the fuel injectors for proper functionality. This can be achieved through the utilization of a fuel injector test kit or by seeking professional mechanical evaluation.

Fuel Pressure Regulator Checks

The fuel pressure regulator is critical in maintaining the system’s fuel pressure at optimal levels. A malfunctioning regulator can precipitate emission-related issues and diminish engine performance.

Symptoms of Regulator Failure

Indicators of a failing fuel pressure regulator include diminished fuel efficiency, engine stalling, and increased emissions. For further insights into diagnosing fuel system malfunctions, refer to this resource.

Replacement Procedure

The replacement of a defective fuel pressure regulator requires the relief of fuel system pressure, disconnection of the regulator, and the installation of a new unit. Adherence to the manufacturer’s guidelines is essential for this procedure.

Fuel Quality Considerations

The utilization of high-quality fuel is crucial for the preservation of a clean and efficient fuel system. The fuel type employed can have a profound impact on emissions.

Recommended Fuel Types for BMW Engines

BMW advocates for the use of premium unleaded gasoline across most models. Adherence to this fuel type recommendation can optimize engine performance and minimize emissions.

Fuel Additives That Help Reduce Emissions

Certain fuel additives are designed to cleanse the fuel system and diminish emissions. Periodic application of these additives can aid in maintaining fuel system health.

Resolving Software and ECU Issues Affecting Emissions

Addressing software and ECU malfunctions is paramount for rectifying emissions-related issues in BMWs. Contemporary vehicles depend on advanced software to oversee numerous systems, including those responsible for emissions control. Suboptimal or corrupted software can precipitate an escalation in emissions, concomitant with a decline in performance, and may also provoke the illumination of warning lights on the dashboard.

BMW Software Updates and Their Impact

BMW periodically disseminates software updates aimed at enhancing vehicle performance, rectifying bugs, and ensuring adherence to emissions standards. These updates exert a profound influence on the functionality of emissions control systems.

Checking for Available Updates

BMW proprietors can access available software updates through their local dealership or via online platforms provided by BMW. It is imperative to possess the correct Vehicle Identification Number (VIN) to guarantee the application of the appropriate updates.

Dealer vs. Independent Programming Options

While dealerships possess the requisite tools and training for software updates, some independent entities also offer this service. It is, thus, crucial to select a reputable independent shop with a proven track record in BMW software updates to circumvent potential complications.

DME/ECU Troubleshooting

The Digital Motor Electronics (DME) or Engine Control Unit (ECU) is instrumental in managing engine performance and emissions. The process of troubleshooting DME/ECU malfunctions necessitates specialized tools and expertise.

Common Electronic Control Unit Failures

ECU failures encompass a range of issues, including faulty sensor inputs, software corruption, and hardware malfunctions. Accurate diagnosis of these problems often demands the utilization of advanced diagnostic equipment.

Resetting Adaptation Values

In certain instances, resetting the ECU’s adaptation values can rectify performance and emissions-related issues. This procedure involves the erasure of the learned values that the ECU has accumulated over time.

Addressing BMW-Specific Software Recalls

BMW may issue software recalls to address specific emissions-related issues. Owners can verify if their vehicle is affected by visiting the BMW website or contacting a dealership.

Checking Your VIN for Recalls

To ascertain if a recall is applicable, owners must provide their VIN to BMW or utilize online recall lookup tools. This ensures the retrieval of accurate information specific to the vehicle in question.

What to Expect During Software Updates

During a software update, the vehicle’s systems will be reprogrammed with the latest software. This process typically spans between 30 minutes to several hours, contingent upon the complexity of the update.

| Update Type | Typical Duration | Expected Outcome |

|---|---|---|

| Simple Software Update | 30 minutes – 1 hour | Improved performance, resolved issues |

| Complex Software Update | 1-3 hours | Enhanced emissions control, fixed bugs |

| ECU Reprogramming | 2-4 hours | Optimized engine performance, updated parameters |

Engine Performance Optimization for Emissions Control

Optimizing engine performance is paramount for emissions reduction and environmental stewardship. By concentrating on pivotal engine components and systems, BMW proprietors can markedly elevate their vehicle’s emissions standards.

Spark Plug and Ignition System Maintenance

Consistent upkeep of spark plugs and the ignition apparatus is imperative for peak engine functionality. Degraded or soiled spark plugs precipitate diminished efficiency and augmented emissions.

Selecting the Correct Spark Plugs

The selection of appropriate spark plugs necessitates consideration of heat range and electrode composition. Platinum and iridium spark plugs exhibit extended lifespan and superior performance relative to conventional copper variants.

Ignition Coil Inspection and Replacement

Regular scrutiny of ignition coils for wear or damage is imperative. Replacement of defective coils averts misfires and sustains optimal engine performance.

Air Filter and Mass Air Flow Sensor Service

A pristine air filter and a functioning Mass Air Flow (MAF) sensor are indispensable for precise air-fuel mixture determinations.

Cleaning the MAF Sensor

The MAF sensor can be cleaned with specialized agents. Adherence to the manufacturer’s guidelines is critical to prevent sensor damage.

Air Filter Selection and Replacement

The selection of an air filter must balance filtration efficacy with airflow. Regular substitution, typically every 15,000 to 30,000 miles, is advisable.

Engine Timing and Valve Adjustments

Proper engine timing and valve adjustments are crucial for optimal performance and emissions control.

VANOS System Maintenance

The VANOS system in BMW vehicles governs valve timing. Regular maintenance, encompassing oil changes and filter replacements, is essential for its durability.

Valvetronic System Troubleshooting

The Valvetronic system modulates valve lift. Troubleshooting entails verification of software updates and examination of electrical connections and actuators.

Professional Solutions for Complex Emission Problems

In the face of intricate emission challenges within your BMW, the imperative to discern when professional intervention is necessary cannot be overstated. Such complexities often necessitate specialized diagnostic capabilities and advanced repair technologies, beyond the scope of amateur endeavors.

When to Consult a BMW Specialist

Recognition of the limitations of DIY solutions in addressing emission-related maladies is paramount to averting potential vehicular harm. Indicators that DIY efforts are insufficient include:

- Persistent emission problems despite troubleshooting efforts

- Unusual noises or vibrations from the engine or exhaust system

- Dashboard warning lights that remain illuminated after resetting

Signs That DIY Isn’t Sufficient

Should your initial troubleshooting endeavors fail to yield resolution, the necessity for professional consultation becomes evident. Equally, any uncertainty regarding diagnosis or apprehension towards repair execution warrants expert intervention.

Finding a Qualified BMW Technician

Identification of a competent BMW technician necessitates verification of certifications from esteemed bodies such as the National Institute for Automotive Service Excellence (ASE). Soliciting recommendations from acquaintances, perusing online testimonials, or consulting with local automotive communities can also be instrumental in this quest.

Dealership vs. Independent Shop Considerations

In the deliberation between availing services from a dealership versus an independent mechanic for your BMW’s repair, several factors merit consideration:

| Factor | Dealership | Independent Shop |

|---|---|---|

| Expertise | Specialized knowledge of BMW models | Often have experience with various BMW models |

| Cost | Generally more expensive | Can be more cost-effective |

| Warranty | Typically maintain manufacturer warranty | May offer their own warranty |

Comparing Service Options

Dealerships frequently possess cutting-edge diagnostic tools and software updates, potentially offering a more comprehensive service. In contrast, independent shops might present a more economical alternative.

Questions to Ask Before Service

Before entrusting your vehicle to repair services, pose inquiries regarding the technician’s familiarity with your BMW model, the anticipated repair cost and duration, and any warranties provided.

Cost Expectations for Professional Repairs

The financial outlay for professional rectification of complex emission issues can exhibit considerable variability, influenced by the specific nature of the problem and the chosen repair facility.

Common Repair Price Ranges

For instance, the replacement of a catalytic converter might incur expenses ranging from $500 to $2,000, whereas the software update of the Engine Control Unit (ECU) could fall within the $100 to $500 bracket.

Warranty Considerations

Verify the status of your vehicle’s manufacturer warranty or inquire about any warranties extended by the repair shop for both parts and labor.

Conclusion

The recent escalation in BMW emissions necessitates a multifaceted strategy, encompassing a thorough comprehension of emission control mechanisms, the identification of malfunctions, and the execution of routine maintenance. Adherence to this directive empowers BMW proprietors to diminish emissions and uphold vehicular efficiency.

Adherence to a regimen of BMW maintenance is paramount for emission reduction. This regimen includes the replacement of oxygen sensors, the inspection of catalytic converters, and the cleansing of EGR systems. Vigilance in these maintenance activities guarantees that the BMW adheres to stringent emission benchmarks.

This comprehensive guide delineates the requisite steps for the diagnosis and rectification of emission-related anomalies in BMW automobiles. Adoption of these protocols enables proprietors to enhance environmental purity while preserving vehicular performance and operational efficacy.

FAQ

What are the primary causes of increased emissions in BMW vehicles?

The primary causes include faulty oxygen sensors, clogged fuel injectors, malfunctioning catalytic converters, and issues with the EGR system.

How do I diagnose emission problems in my BMW?

Diagnosing emission problems involves using OBD-II diagnostic tools to read error codes, performing visual inspections to identify issues such as vacuum leaks, and checking the condition of emission control components.

What is the role of the oxygen sensor in BMW emission control?

The oxygen sensor monitors the oxygen levels in the exhaust gases and provides feedback to the engine control unit to adjust the air-fuel mixture, ensuring optimal combustion and minimizing emissions.

How do I know if my BMW’s catalytic converter is failing?

Signs of a failing catalytic converter include decreased performance, increased emissions, and diagnostic trouble codes related to the catalytic converter. A visual inspection can also reveal damage or clogging.

Can I clean a clogged catalytic converter, or does it need to be replaced?

In some cases, cleaning a clogged catalytic converter may resolve the issue, but often replacement is necessary, if the converter is damaged or severely clogged.

What is the EGR system, and how does it affect emissions?

The EGR (Exhaust Gas Recirculation) system reduces emissions by recirculating a portion of the exhaust gases back into the engine cylinders, lowering the combustion temperature and reducing NOx emissions.

How often should I perform maintenance on my BMW’s fuel injectors?

Regular maintenance, such as cleaning clogged fuel injectors, should be performed as recommended by the manufacturer or when symptoms of faulty injectors appear, such as decreased performance or increased emissions.

What are the benefits of keeping my BMW’s software up to date?

Keeping your BMW’s software up to date can improve engine performance, reduce emissions, and resolve issues related to the engine control unit, ensuring your vehicle runs efficiently and environmentally friendly.

When should I consult a professional for emission-related issues?

Consult a professional if you are unsure about diagnosing or repairing emission-related issues, or if your vehicle is experiencing complex problems that require specialized tools and expertise.

What are the differences between dealership and independent shop services for BMW emission repairs?

Dealership services often come with the assurance of manufacturer-trained technicians and genuine parts, while independent shops may offer more competitive pricing and personalized service. Consider your priorities when choosing between the two.

How can I verify that repairs have resolved the emission issues in my BMW?

After repairs, use OBD-II diagnostic tools to check for any remaining trouble codes, monitor your vehicle’s performance, and ensure that emission-related issues are resolved.