You’ve just installed new brake rotors on your vehicle, taken it for a test drive, and noticed the wheels are hot to the touch. Should you be concerned? Many vehicle owners experience this situation and wonder if the heat is normal or indicates a problem. In this comprehensive guide, we’ll explain why new rotors get hot after installation, how to differentiate between normal heat and problematic overheating, and when you should seek professional assistance.

Understanding How Brakes Generate Heat

Before we discuss why new rotors get hot, it’s important to understand that heat generation is a fundamental aspect of how your braking system works. When you press the brake pedal, hydraulic pressure forces the brake pads to clamp against the rotors (also called discs). This creates friction, which converts your vehicle’s kinetic energy (motion) into thermal energy (heat).

This heat generation is completely normal and necessary for your vehicle to slow down. In fact, during normal driving conditions, your brake rotors can reach temperatures between 150°F to 400°F (65°C to 204°C), depending on your driving style, vehicle weight, and braking frequency.

The more aggressively you brake or the heavier your vehicle, the more heat will be generated. This is why performance vehicles often have larger, ventilated rotors designed to dissipate heat more efficiently.

Normal Heat vs. Problematic Overheating

Normal Heat Characteristics

- Rotors feel warm to hot after driving but cool down within 30-60 minutes

- All wheels have relatively similar temperature

- No unusual smells or smoke

- No changes in braking performance

- Heat dissipates more quickly as break-in period progresses

Problematic Overheating Signs

- Rotors extremely hot (can’t touch for even a second)

- One wheel significantly hotter than others

- Burning smell or visible smoke

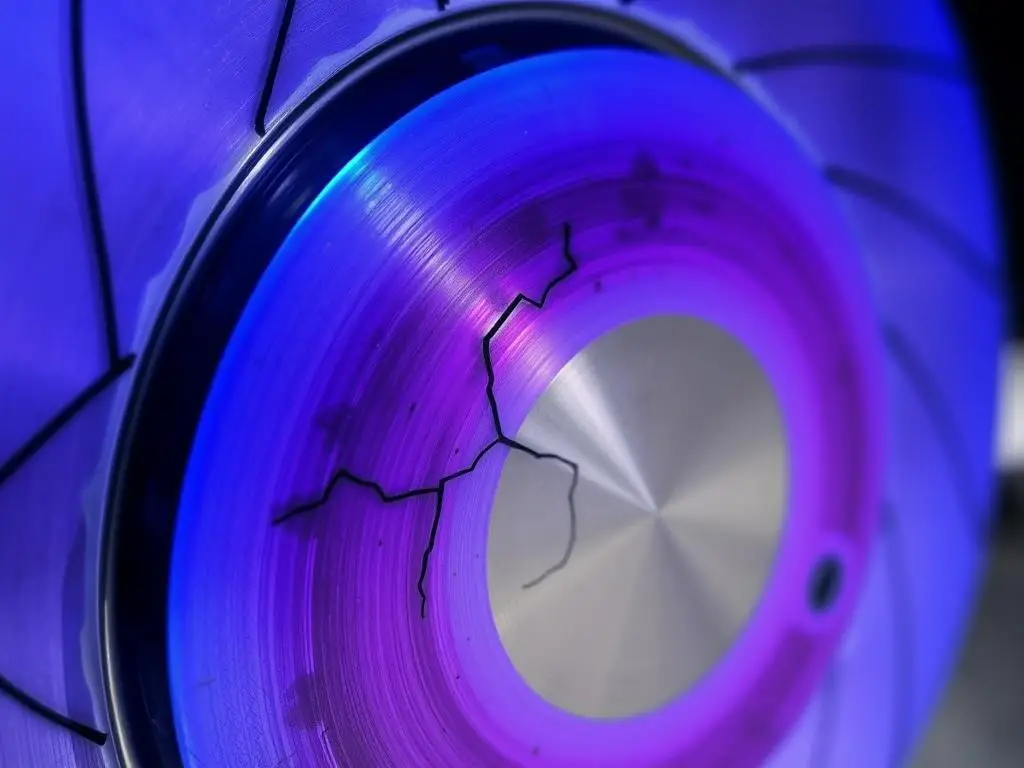

- Blue/purple discoloration on rotors

- Reduced braking performance or brake fade

- Heat persists even after extended cooling period

Why New Rotors Normally Get Hot After Installation

It’s completely normal for newly installed rotors to generate more heat than usual during the first few hundred miles. Here are the primary reasons why:

1. The Bedding-In Process

New brake pads and rotors need to go through a “bedding-in” or “break-in” process. This involves the transfer of a thin layer of brake pad material onto the rotor surface, creating an optimal friction interface. During this process, microscopic high spots on both the pads and rotors are smoothed out, resulting in more even contact and improved braking performance.

This material transfer process naturally generates additional heat. You might notice a slight burning smell during this period, which is typically the resin in the brake pads curing as they reach operating temperature for the first time.

2. Surface Treatments and Coatings

Many new rotors come with protective coatings or surface treatments to prevent rust during shipping and storage. These coatings burn off during the first few braking cycles, which can temporarily increase heat generation and sometimes produce a distinct smell.

3. Machining Marks and Surface Irregularities

New rotors often have machining marks and minor surface irregularities that create additional friction until they’re smoothed out through normal use. This increased friction generates more heat during the initial break-in period.

Proper Break-In Procedure for New Rotors

Following the correct break-in procedure helps ensure optimal performance and longevity of your new brake components while minimizing excessive heat:

- Avoid hard braking for the first 200-300 miles. Drive normally but avoid aggressive stops that could overheat the new components before they’re properly bedded.

- Perform 8-10 moderate stops from 35-40 mph down to 5 mph. Apply the brakes firmly but not aggressively, allowing about 30 seconds between stops for cooling.

- Drive at moderate speeds for 5-10 minutes without using the brakes. This allows the heat to dissipate gradually without “imprinting” the rotor.

- Perform 2-3 slightly harder stops from 45-50 mph down to 5 mph. Again, allow cooling time between stops.

- Allow the brakes to cool completely. Park the vehicle for at least an hour before driving again if possible.

Important: Never come to a complete stop during the bedding process except for the final stop. This prevents uneven material deposits that can cause vibration. Also, avoid stopping and holding the brake pedal down while the rotors are hot, as this can create “hot spots” or warp the rotors.

When Hot Rotors Indicate a Problem

While some heat is normal, excessive heat can indicate installation issues or other brake system problems. Here are common causes of problematic overheating:

1. Stuck Caliper or Piston

If a caliper piston becomes stuck in the applied position, it will cause the brake pad to remain in constant contact with the rotor, generating excessive heat even when you’re not braking. This often affects only one wheel, creating a noticeable temperature difference between wheels.

2. Binding Slide Pins

On floating caliper designs, the caliper slides on pins or rails to center itself over the rotor. If these slide pins become corroded or aren’t properly lubricated during installation, the caliper can bind and cause the pads to drag against the rotor.

3. Improperly Adjusted Parking Brake

On vehicles with rear drum brakes or drum-in-hat parking brake systems, improper adjustment can cause the shoes to drag against the drum, generating excess heat. The Bentley manual specifies a gap of 1.0-3.0mm between the parking brake lever and stop when properly adjusted.

4. Collapsed Brake Hose

A deteriorated brake hose can collapse internally, creating a one-way valve effect. This allows pressure to reach the caliper when you apply the brakes but prevents it from releasing completely, causing the pads to drag against the rotor.

5. Contaminated Brake Fluid

Contaminated brake fluid can contain particles that interfere with the proper operation of the master cylinder or caliper pistons, preventing them from fully retracting. This is why it’s important to flush the brake system when installing new components.

6. Overfilled Master Cylinder

If the master cylinder reservoir is overfilled, there may not be enough space for the fluid to expand as it heats up. This can create pressure in the system that prevents the caliper pistons from fully retracting.

How to Diagnose Problematic Rotor Heat

If you suspect your new rotors are getting hotter than they should, here are some diagnostic steps you can take:

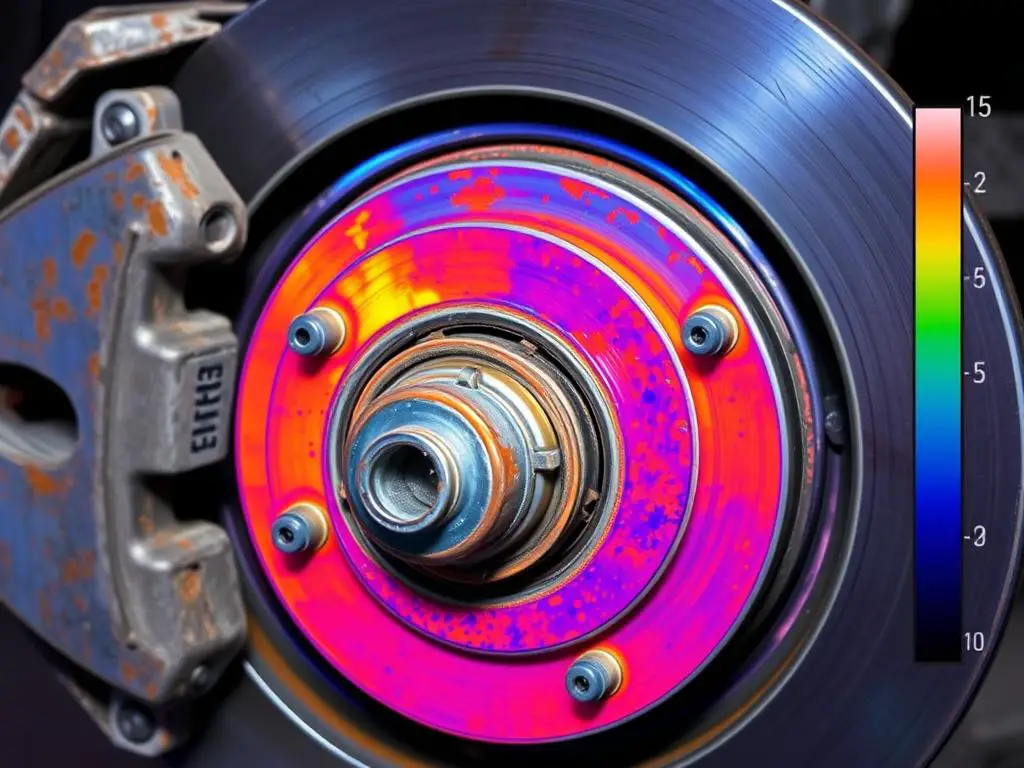

1. Compare Wheel Temperatures

After a short drive, carefully check all four wheels for temperature differences. You can use an infrared thermometer for precise measurements or carefully hold the back of your hand near (not touching) each wheel. If one wheel is significantly hotter than the others, it likely indicates a problem with that specific brake assembly.

2. Check for Free Wheel Rotation

Jack up the vehicle safely and spin each wheel by hand. They should rotate freely and continue spinning for several rotations before stopping. If a wheel stops quickly or feels resistant, there may be brake drag.

3. Inspect Caliper Movement

With the wheel removed, check that the caliper moves freely on its slide pins. The pins should be clean and properly lubricated with high-temperature brake grease. If they’re corroded or binding, clean and lubricate them according to your vehicle’s service manual.

4. Examine Parking Brake Adjustment

Verify that the parking brake fully releases and that the lever returns to its rest position. On many vehicles, there should be a small gap (typically 1-3mm) between the lever and its stop when properly adjusted.

5. Check for Rotor Discoloration

Blue or purple discoloration on the rotor surface indicates it has been subjected to excessive heat, which can change the metallurgical properties of the rotor and reduce its effectiveness.

When to Seek Professional Help

Safety Warning: Brake system issues should never be ignored. If you experience any of the following symptoms, stop driving the vehicle and seek professional assistance immediately:

- Extreme heat – Wheels too hot to touch even briefly

- Smoke or strong burning smell coming from the wheels

- Reduced braking performance or spongy brake pedal

- Brake warning light illuminated on dashboard

- Grinding, squealing, or other unusual noises when braking

- Vehicle pulling to one side during braking

- Vibration or pulsation in the brake pedal

A professional technician has the tools, equipment, and expertise to properly diagnose and fix brake system issues. They can perform pressure tests, check for internal caliper problems, and properly bleed the hydraulic system to remove air bubbles.

Maintenance Tips for Optimal Brake Performance

To ensure your new rotors perform optimally and have a long service life, follow these maintenance tips:

Regular Maintenance

- Check brake fluid level and condition regularly. Fluid should be clear to amber in color, not dark or cloudy.

- Flush brake fluid every 2-3 years or as recommended by your vehicle manufacturer.

- Inspect brake pads for wear at least twice a year.

- Clean and lubricate caliper slide pins during pad replacement.

- Check parking brake adjustment annually.

Driving Habits

- Avoid riding the brakes, especially on long downhill stretches.

- Use engine braking (downshifting) to assist on steep descents.

- Allow cooling time after hard braking before parking.

- Avoid unnecessary heavy loads that increase braking demands.

- Drive smoothly and anticipate stops to reduce hard braking.

“The most effective brake maintenance is preventive. Regular inspections and fluid changes can prevent most common brake issues before they develop into expensive repairs or safety hazards.”

Frequently Asked Questions About New Rotors

How long does it take for new rotors to break in?

The initial break-in process typically takes about 300-500 miles of normal driving. During this period, you may notice slightly different brake feel and increased heat generation. The formal bedding-in procedure (series of controlled stops) should be performed within the first 50 miles, but the complete transfer layer development continues over several hundred miles.

Is it normal for new rotors to make noise?

Some minor noise during the first few dozen braking cycles is normal as the pads and rotors establish their friction surfaces. However, persistent squealing, grinding, or other loud noises are not normal and should be investigated. These could indicate improper installation, low-quality components, or other issues.

How hot is too hot for brake rotors?

During normal operation, rotors typically reach 300-400°F (150-200°C). Temperatures up to 600°F (315°C) can occur during hard braking but should quickly dissipate. If you cannot hold your hand near (not touching) the wheel for more than a few seconds, or if the rotor shows blue discoloration, the temperature is excessive and indicates a problem.

Should I replace rotors in pairs?

Yes, rotors should always be replaced in pairs (both front or both rear) to ensure even braking performance. Uneven rotor thickness or surface condition between the left and right sides can cause the vehicle to pull to one side during braking and lead to uneven pad wear.

Do I need to replace calipers when replacing rotors?

Not necessarily. Calipers typically last much longer than rotors and pads. However, if a caliper is leaking, sticking, or showing signs of uneven wear, it should be replaced. It’s also good practice to inspect caliper slide pins and boots during rotor replacement and clean/lubricate or replace them as needed.

Understanding all brake components helps diagnose heat-related issues

Conclusion: When to Worry About Hot Rotors

Some heat generation is a normal and necessary part of your vehicle’s braking system, especially with newly installed rotors that are going through the bedding-in process. However, excessive heat that persists beyond the break-in period or is accompanied by other symptoms should be addressed promptly.

Remember these key takeaways:

- New rotors will naturally run hotter during the first 300-500 miles as they bed in

- Follow proper break-in procedures to establish optimal friction surfaces

- Compare temperatures between wheels—significant differences indicate a problem

- Blue discoloration, smoke, or burning smells are never normal

- Regular maintenance and proper driving habits extend brake component life

By understanding the difference between normal heat and problematic overheating, you can ensure your new rotors provide safe, effective braking performance for many miles to come.