Reliable performance is crucial for Kubota tractor owners and operators. Issues with the hydrostatic transmission can significantly impact the efficiency and productivity of the equipment.

Understanding the common transmission problems and knowing how to diagnose and repair them is essential for maintaining optimal performance. This article will provide a comprehensive guide on identifying and fixing hydrostatic transmission issues in Kubota equipment.

Key Takeaways

- Common signs of hydrostatic transmission problems

- Step-by-step diagnosis techniques

- Effective repair methods for Kubota transmissions

- Tips for maintaining optimal transmission performance

- Importance of regular maintenance for prolonging equipment lifespan

Understanding Kubota Hydrostatic Transmissions

Understanding the intricacies of Kubota hydrostatic transmissions is essential for tractor owners who want to maintain their equipment effectively. Kubota hydrostatic transmissions are a crucial component of many Kubota tractors, providing smooth and efficient power transmission.

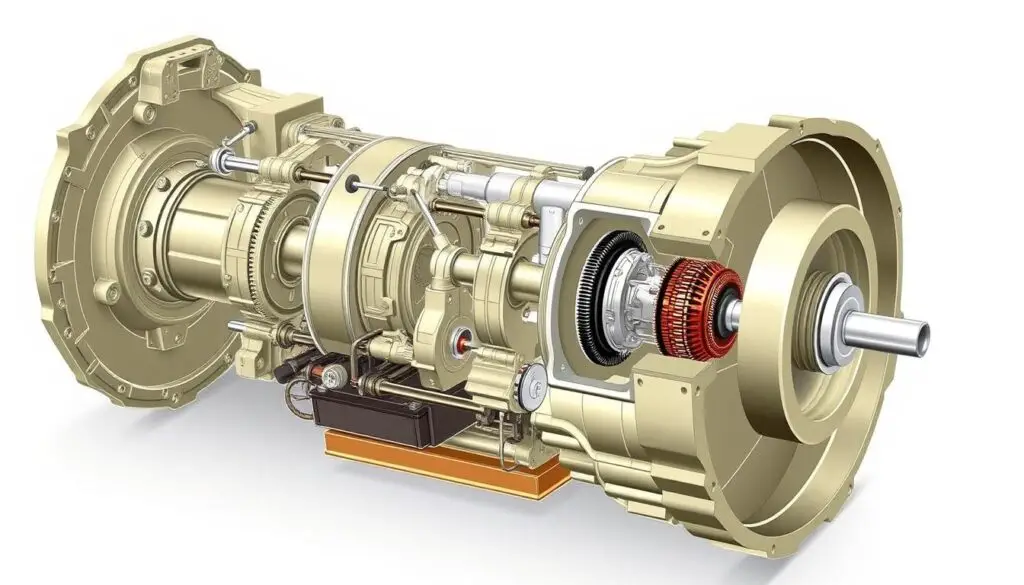

How Hydrostatic Transmissions Work

Hydrostatic transmissions use fluid pressure to transmit power, allowing for smooth and continuous speed adjustment without the need for manual gear shifting. This is achieved through a combination of a hydraulic pump and a hydraulic motor. The pump converts mechanical energy into hydraulic energy, which is then converted back into mechanical energy by the motor to drive the tractor’s wheels.

Components of Kubota Hydrostatic Systems

The key components of Kubota hydrostatic transmission systems include:

- The hydraulic pump, which generates the fluid pressure.

- The hydraulic motor, which converts the fluid pressure back into mechanical energy.

- The control valves, which regulate the flow of hydraulic fluid.

- The hydraulic fluid itself, which is essential for the transmission’s operation.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates fluid pressure |

| Hydraulic Motor | Converts fluid pressure into mechanical energy |

| Control Valves | Regulates hydraulic fluid flow |

Common Models and Their Specific Characteristics

Kubota offers a range of hydrostatic transmission models, each with its specific characteristics. For instance, some models are designed for heavy-duty applications, while others are suited for lighter tasks. Understanding the specifications of your Kubota tractor’s transmission is crucial for effective maintenance and troubleshooting.

“The quality of the hydraulic fluid is paramount to the longevity and performance of the hydrostatic transmission system.” –

By understanding how Kubota hydrostatic transmissions work and their key components, tractor owners can better diagnose and address potential issues, ensuring their equipment remains in optimal working condition.

Common Kubota Hydrostatic Transmission Problems: What to Look Out For and How to Fix

Kubota hydrostatic transmission problems can be frustrating, but understanding the common issues can help you diagnose and fix them effectively. Hydrostatic transmissions are complex systems that rely on hydraulic fluid to transmit power, and issues can arise from various components.

Loss of Power and Slow Response

A loss of power or slow response in your Kubota equipment can be due to low hydraulic fluid levels, internal leaks, or worn-out components. To fix this, first check the fluid levels and top them off if necessary. Inspect the system for leaks and repair them. If the problem persists, consider replacing worn-out parts.

Unusual Noises and Vibrations

Unusual noises or vibrations can indicate problems with the transmission’s mechanical components or hydraulic system. Check for loose or damaged parts and tighten or replace them as needed. Also, inspect the hydraulic fluid for contamination, as dirty fluid can cause unusual noises.

Overheating Issues

Overheating can occur due to low fluid levels, blocked cooling systems, or excessive workload. Ensure the fluid level is adequate and the cooling system is clear of debris. Reducing the workload or improving airflow around the transmission can also help mitigate overheating issues.

Leaking Hydraulic Fluid

Leaks in the hydraulic system can lead to a drop in fluid levels, causing transmission problems. Inspect the system for signs of leaks and repair or replace damaged seals or hoses. Regularly checking the fluid level can help identify leaks early.

Transmission Not Engaging or Disengaging

Issues with the transmission engaging or disengaging can be due to problems with the control system or hydraulic pressure. Check the control linkage for proper adjustment and ensure there are no blockages. Also, verify that the hydraulic pressure is within the recommended specifications.

By understanding these common Kubota hydrostatic transmission problems and following the steps outlined above, you can diagnose and fix issues effectively, ensuring your equipment runs smoothly and efficiently.

Diagnosing Hydrostatic Transmission Issues

Diagnosing hydrostatic transmission issues in your Kubota equipment requires a thorough and systematic approach. This involves a combination of visual inspections, fluid checks, performance testing, and the use of advanced diagnostic tools.

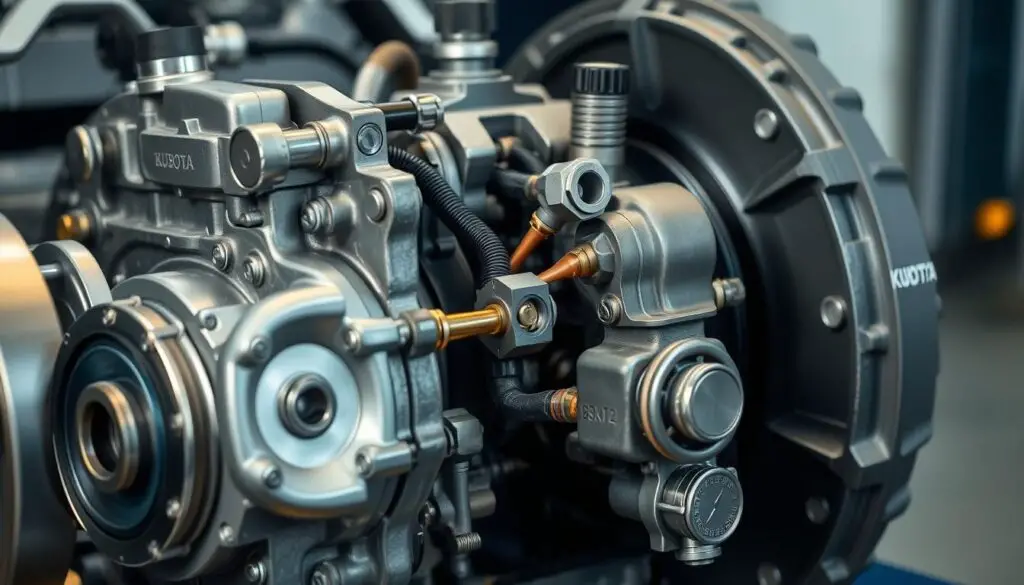

Visual Inspection Techniques

A visual inspection is the first step in diagnosing hydrostatic transmission problems. Look for signs of wear, damage, or leaks around the transmission and its components. Check the condition of hoses, fittings, and seals, as these are common areas where issues arise.

Checking Fluid Levels and Quality

The condition and level of the hydraulic fluid are critical to the proper functioning of the hydrostatic transmission. Check the fluid level against the manufacturer’s recommendations and inspect the fluid’s color and consistency. Dirty or degraded fluid can lead to transmission problems.

Testing Pressure and Performance

Testing the pressure and performance of the hydrostatic transmission helps identify issues related to its operation. Use a pressure gauge to check the system’s pressure against the manufacturer’s specifications. Observe the transmission’s performance under load to identify any irregularities.

Using Diagnostic Tools for Advanced Troubleshooting

For more complex issues, advanced diagnostic tools can provide detailed insights into the transmission’s operation. These tools can help identify problems that are not apparent through visual inspections or basic testing. Use these tools to monitor system parameters and pinpoint the source of the issue.

| Diagnostic Step | Purpose | Tools Required |

|---|---|---|

| Visual Inspection | Identify signs of wear or damage | None |

| Fluid Check | Assess fluid condition and level | Fluid dipstick, clean cloth |

| Pressure Testing | Evaluate system pressure | Pressure gauge |

| Advanced Troubleshooting | Monitor system parameters | Diagnostic software, connection cables |

Step-by-Step Repair Solutions

Effective Kubota hydrostatic transmission repair starts with diagnosing the problem, followed by targeted fixes for fluid-related, mechanical, and control system issues. By understanding the root cause of the problem, you can apply the appropriate repair solution to get your equipment back in working order.

Addressing Fluid-Related Problems

Fluid-related issues are common in Kubota hydrostatic transmissions. These can include low fluid levels, contaminated fluid, or leaks. Regular maintenance is key to preventing these issues.

Fluid Replacement Procedure

Replacing the fluid in your Kubota hydrostatic transmission involves several steps:

- Drain the old fluid completely.

- Replace the filter (if applicable).

- Refill with the recommended type and amount of fluid.

As emphasized by Kubota experts, “Using the correct fluid is crucial for the longevity and performance of your hydrostatic transmission.”

Filter Maintenance and Replacement

The filter plays a critical role in maintaining the cleanliness of the fluid. Regularly inspect and replace the filter as needed to prevent contamination.

Fixing Mechanical Issues

Mechanical problems can arise from wear and tear on components such as the pump, motor, and drive belts. Identifying these issues early can prevent more significant problems.

Pump and Motor Repairs

Repairing or replacing the pump and motor requires specialized tools and knowledge. It’s essential to follow the manufacturer’s guidelines for these procedures.

Drive Belt Adjustments and Replacements

Drive belts that are worn or misaligned can cause transmission problems. Regularly inspect the belts and adjust or replace them as necessary.

“Proper maintenance of drive belts is essential for the smooth operation of your Kubota hydrostatic transmission.”

Dealing with Control System Problems

Control system issues can affect the performance of your Kubota hydrostatic transmission. These can include problems with linkages and electronic controls.

Linkage Adjustments

Linkages that are worn or misaligned can cause issues with transmission engagement and disengagement. Adjusting these linkages can often resolve the problem.

Electronic Control Troubleshooting

For transmissions with electronic controls, troubleshooting involves checking the electrical connections, sensors, and control modules. Using diagnostic tools can help identify the source of the problem.

By following these step-by-step repair solutions, you can effectively address common Kubota hydrostatic transmission problems and maintain your equipment in optimal working condition.

Preventative Maintenance for Long-Term Reliability

A proactive approach to maintenance can significantly enhance the reliability of your Kubota hydrostatic transmission. By adopting a routine maintenance schedule, you can identify and address potential issues before they become major problems.

Recommended Maintenance Schedule by Hour Usage

Following the manufacturer’s recommended maintenance schedule is crucial. For Kubota equipment, this typically involves regular checks at intervals of 50, 100, and 200 hours of operation.

| Hour Interval | Maintenance Task |

|---|---|

| 50 Hours | Check hydraulic fluid levels, inspect for leaks |

| 100 Hours | Change hydraulic fluid, inspect transmission components |

| 200 Hours | Replace transmission filters, check for wear on moving parts |

Proper Operating Techniques to Reduce Wear

Operating your Kubota equipment correctly can significantly reduce wear on the hydrostatic transmission. Avoid sudden starts and stops, and ensure the transmission is fully engaged before operating under load.

“Regular maintenance and proper operation are key to extending the life of your Kubota hydrostatic transmission.”

Seasonal Care and Storage Recommendations

Before storing your Kubota equipment for an extended period, perform a thorough maintenance check. This includes changing the hydraulic fluid and ensuring the transmission is in good condition.

DIY vs. Professional Maintenance: When to Call the Experts

While some maintenance tasks can be performed by the operator, complex issues or tasks beyond your expertise should be handled by professionals. Regular inspections by a qualified technician can help identify potential problems early.

By following these guidelines and maintaining a proactive stance on maintenance, you can ensure the long-term reliability of your Kubota hydrostatic transmission.

Conclusion

Understanding and maintaining your Kubota hydrostatic transmission is crucial for optimal performance and longevity. By diagnosing issues early and following a regular maintenance schedule, you can prevent costly repairs and ensure your equipment runs smoothly.

The Kubota hydrostatic transmission repair guide provided in this article has outlined the common problems, diagnostic techniques, and step-by-step repair solutions. By addressing issues such as loss of power, unusual noises, and leaking hydraulic fluid, you can restore your transmission to its optimal state.

Regular transmission maintenance, including checking fluid levels and quality, is essential for preventing wear and tear. By adopting proper operating techniques and following the recommended maintenance schedule, you can extend the life of your Kubota hydrostatic transmission.

By applying the knowledge gained from this guide, you can take proactive steps to maintain your Kubota equipment, reduce downtime, and improve overall productivity. Effective maintenance and repair of your Kubota hydrostatic transmission will ensure reliable performance and longevity.

FAQ

What are the most common problems with Kubota hydrostatic transmissions?

Common issues include loss of power, unusual noises, overheating, leaking hydraulic fluid, and transmission not engaging or disengaging properly.

How do I diagnose a problem with my Kubota hydrostatic transmission?

Diagnosis involves a visual inspection, checking fluid levels and quality, testing pressure and performance, and using diagnostic tools for advanced troubleshooting.

What is the recommended maintenance schedule for Kubota hydrostatic transmissions?

The recommended maintenance schedule varies by hour usage, but typically includes regular fluid checks, filter maintenance, and inspections of key components.

Can I perform maintenance on my Kubota hydrostatic transmission myself?

While some maintenance tasks can be performed DIY, such as fluid checks and filter replacements, more complex repairs may require professional expertise.

How can I prevent problems with my Kubota hydrostatic transmission?

Preventative measures include following a recommended maintenance schedule, using proper operating techniques, and storing the equipment correctly during seasonal downtime.

What are the signs of a failing Kubota hydrostatic transmission pump?

Signs of a failing pump include unusual noises, decreased performance, and increased temperature.

How do I check the hydraulic fluid level in my Kubota hydrostatic transmission?

Checking the hydraulic fluid level involves locating the reservoir, checking the level against the recommended minimum and maximum marks, and ensuring the fluid is at the correct level.

What type of hydraulic fluid is recommended for Kubota hydrostatic transmissions?

Kubota recommends using high-quality hydraulic fluid that meets their specifications, typically found in the owner’s manual or manufacturer’s guidelines.