The turbocharger’s fundamental role is to augment engine performance by intensifying air compression within the combustion chamber. Yet, its malfunction can precipitate a decline in engine efficiency, potentially resulting in substantial damage.

Recognizing turbo failure symptoms at an early stage is imperative to avert further issues. Indicators often include anomalous sounds, diminished power output, and copious smoke emission. Grasping the reasons behind a bad turbo facilitates the implementation of preventive strategies, thus ensuring the turbocharger’s prolonged functionality.

Key Takeaways

- Early detection of turbo failure symptoms is vital.

- A bad turbo can lead to decreased engine performance.

- Regular maintenance can help prevent turbocharger failure.

- Unusual noises and excessive smoke are common indicators.

- Understanding the causes can aid in prevention.

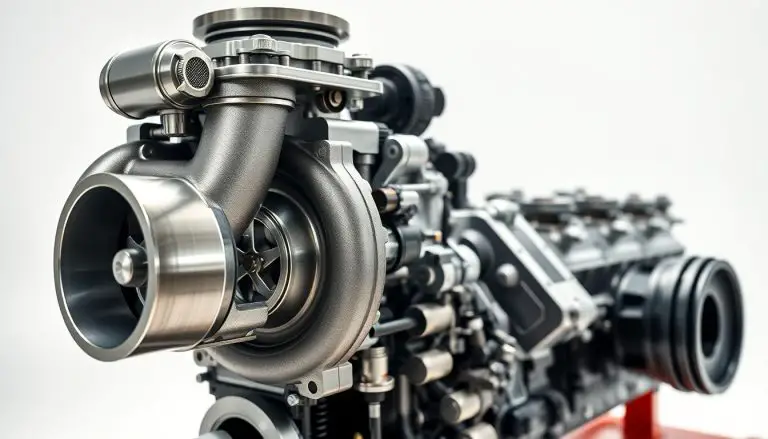

Understanding Turbochargers and Their Function

The intricacies of turbocharger operation are pivotal in grasping their profound influence on engine performance and overall vehicle efficiency. These sophisticated components are instrumental in augmenting engine capabilities, thus enhancing vehicle performance.

How Turbochargers Work

Turbochargers harness the exhaust gases of an engine to power a turbine, which then compels a compressor to compress air. This air is then forcibly introduced into the engine’s combustion chamber. This mechanism significantly augments the air available for combustion, leading to a notable increase in power output. The fundamental principle behind turbocharger operation is the utilization of waste energy from exhaust gases to enhance engine efficiency.

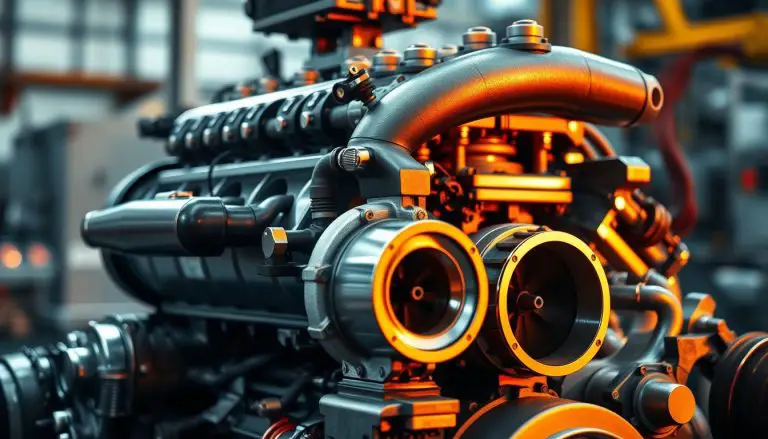

Types of Turbochargers in Modern Vehicles

Modern vehicles incorporate diverse turbocharger configurations, including single, twin, and variable geometry turbochargers (VGTs). Each configuration is tailored to fulfill specific performance and efficiency benchmarks. For example, VGTs enhance performance across a broader range of engine speeds through the adjustment of turbine blade angles. For further insights into turbo failure, refer to https://www.dowleys.co.uk/blog/turbo-failure-what-can-i-do.

Benefits of Turbocharged Engines

Turbocharged engines present several advantages, including enhanced power output, superior fuel efficiency, and diminished emissions. By enabling smaller engines to match the power of larger, naturally aspirated engines, turbocharging facilitates engine downsizing without compromising performance. This downsizing leads to enhanced fuel economy and lower emissions, rendering turbocharged engines a compelling choice for eco-conscious consumers.

Common Turbo Failure Symptoms and Bad Turbo Reasons

Recognizing the early signs of turbocharger failure is imperative to avert engine damage and the resultant financial burden of repairs. The failure of a turbocharger can manifest through a variety of symptoms, which, if identified promptly, enable timely intervention to mitigate severe consequences.

Loss of Power and Acceleration

The primary indicator of a failing turbocharger is a discernible diminution in engine power and acceleration. This phenomenon arises from the turbocharger’s malfunction, resulting in a reduction in boost pressure and, by extension, a decline in engine performance. If your vehicle’s acceleration is subpar, it may signify a turbocharger failure.

Excessive Exhaust Smoke Colors and Their Meaning

Excessive exhaust smoke can also serve as a symptom of turbocharger failure. The color of the smoke offers insight into the underlying issue:

- Blue or Gray Smoke: Typically indicates oil is being burned, possibly due to turbocharger oil seal failure.

- Black Smoke: Often signifies a rich fuel mixture, which could be due to a faulty turbocharger or other engine issues.

- White Smoke: Usually indicates coolant leakage into the combustion chamber, potentially due to a cracked cylinder head or head gasket.

Distinctive Turbo Noise Issues

Unusual noises can also signal turbocharger problems. These noises can vary and are often categorized into different types.

Whistling and Whining Sounds

A high-pitched whining or whistling noise, notably during acceleration, can indicate a problem with the turbocharger’s compressor or turbine wheels. This could be due to wear, misalignment, or damage.

Rattling and Grinding Noises

Rattling or grinding noises may suggest more severe internal damage, such as bearing failure or contact between the turbine or compressor wheel and the housing. These sounds require immediate attention to prevent further damage.

Warning Lights and Error Codes

Modern vehicles are equipped with sophisticated diagnostic systems. If your turbocharger is failing, it may trigger warning lights on your dashboard or generate error codes that can be read with a diagnostic tool. These alerts can provide valuable information about the nature of the problem.

Oil Leaks and Consumption Problems

Turbocharger failure can also lead to oil leaks or increased oil consumption. If the turbocharger’s seals fail, oil can leak into the compressor or turbine, leading to increased oil consumption or visible leaks. Monitoring your vehicle’s oil level and looking for signs of leakage around the turbocharger area is essential.

| Symptom | Possible Cause | Action Required |

|---|---|---|

| Loss of Power | Turbocharger failure, boost pressure loss | Check turbocharger condition, inspect for damage |

| Excessive Exhaust Smoke | Oil leakage, rich fuel mixture, coolant leakage | Diagnose smoke color, inspect engine and turbocharger |

| Unusual Noises | Turbocharger bearing failure, wheel damage | Inspect turbocharger, listen for abnormal sounds during operation |

Primary Causes of Turbocharger Damage

Grasping the fundamental causes of turbocharger malfunction is imperative for preserving engine integrity. Turbochargers, being intricate and subjected to harsh conditions, are prone to various forms of damage.

Oil-Related Issues

Problems stemming from oil are a major contributor to turbocharger failure. The turbocharger’s dependency on engine oil for lubrication underscores the critical nature of oil quality and supply.

Poor Quality Oil

Employment of suboptimal or inappropriate oil grades can precipitate inadequate lubrication, exacerbating wear on turbocharger components. Adherence to the manufacturer’s recommended oil type is paramount for maintaining performance and longevity.

Insufficient Lubrication

Deficient lubrication, often precipitated by low oil levels or clogged oil filters, can induce overheating and failure of the turbocharger. Vigilance in oil changes and filter inspections is essential to avert this scenario.

Foreign Object Damage and Contamination

Ingress of foreign objects into the turbocharger can inflict substantial damage. This may arise from improper installation, debris within the intake system, or worn engine components.

“Foreign object damage is one of the most common causes of turbocharger failure, often resulting from debris or improper maintenance.”

Thorough examination of the intake system and consistent maintenance can significantly reduce this risk.

Carbon and Soot Buildup

Accumulation of carbon and soot within the turbocharger can impede performance and culminate in failure. This phenomenon is frequently a consequence of incomplete combustion, stemming from issues such as faulty fuel injectors or clogged air filters.

Excessive Heat and Pressure Conditions

Turbochargers function under extreme heat and pressure. Excessive heat, often resulting from coolant leaks or faulty thermostats, can compromise the integrity of the turbocharger’s components.

A table summarizing the causes and effects of excessive heat on turbochargers is provided below:

| Cause | Effect |

|---|---|

| Coolant Leaks | Increased Temperature |

| Faulty Thermostats | Overheating |

| Clogged Air Filters | Reduced Cooling Efficiency |

Manufacturing and Design Defects

While less frequent, manufacturing and design flaws can also precipitate turbocharger failure. These imperfections may remain undetected until the turbocharger is subjected to stress.

Regular inspections and monitoring of turbocharger performance can help identify potential issues early on, enabling timely corrective actions.

Diagnosing a Failing Turbocharger

Identifying a malfunctioning turbocharger is imperative for preserving engine efficacy and averting potential damage escalation. A thorough diagnostic process necessitates a blend of visual assessments, performance evaluations, and the deployment of diagnostic apparatus.

Visual Inspection Techniques

The initial phase in diagnosing a turbocharger’s failure entails a visual examination. Vigilance for oil leakage around the turbocharger is paramount, as it often signals seal deterioration. The compressor and turbine blades should be scrutinized for any signs of damage or contamination. Concurrently, the integrity of hoses and connections must be evaluated for wear or damage indicators.

Performance Testing Methods

Performance evaluation is a subsequent step, entailing the monitoring of the turbocharger’s functionality across diverse engine states. Any diminution in power or boost pressure serves as a critical indicator of potential turbocharger malfunction. An uptick in the engine’s exhaust gas temperature also warrants attention, as it may signal a turbocharger-related issue. For a more detailed exploration of related concerns, refer to this page for comprehensive insights.

Diagnostic Tools and Computer Analysis

Contemporary vehicles frequently incorporate onboard diagnostics (OBD) systems, which offer invaluable insights into turbocharger performance. Utilizing a scan tool, one can access trouble codes and track metrics such as boost pressure and turbocharger speed. This data is instrumental in pinpointing turbocharger malfunctions.

When to Seek Professional Diagnosis

In cases of diagnostic ambiguity or when initial assessments fail to resolve the issue, professional intervention is advisable. A skilled mechanic can execute more detailed examinations and deliver a precise diagnosis. They are also equipped to propose repair alternatives and guide on whether to opt for turbocharger refurbishment or replacement.

| Diagnostic Method | Description | Tools Required |

|---|---|---|

| Visual Inspection | Inspect for oil leaks, damage, or debris | None |

| Performance Testing | Monitor boost pressure, power loss | Scan tool, pressure gauge |

| Computer Analysis | Retrieve trouble codes, monitor parameters | Scan tool, OBD software |

Turbo Repair Options and Costs

The failure of a turbocharger necessitates immediate attention and a well-informed decision regarding the appropriate course of action. Upon diagnosing a turbo failure, owners must carefully weigh their options, considering both the immediate and long-term implications of their choice.

Rebuilding vs. Replacement Considerations

The primary decision revolves around whether to rebuild or replace the turbocharger. Rebuilding entails restoring the turbo to its original condition by replacing worn-out parts, offering a cost-effective solution but not always feasible or advisable, depending on the extent of the damage. In contrast, replacement involves installing a new turbocharger, ensuring optimal performance but at a higher upfront cost.

- Rebuilding: Potential cost savings, but the quality depends on the repair service.

- Replacement: Ensures optimal performance and warranty, but is more expensive.

OEM vs. Aftermarket Turbochargers

When opting for replacement, the choice between OEM (Original Equipment Manufacturer) and aftermarket turbochargers emerges. OEM turbochargers, made to the same specifications as the original, are generally more expensive. Aftermarket turbochargers offer comparable performance at a lower cost but may vary in quality.

“The choice between OEM and aftermarket parts often comes down to budget and personal preference regarding warranty and performance guarantees.”

DIY Repair Possibilities and Limitations

For those inclined towards DIY repairs, it’s crucial to understand the limitations and potential risks. While some repairs can be done at home, complex turbocharger issues often require professional expertise.

Some key considerations for DIY repairs include:

- Assessing the extent of the damage accurately.

- Having the necessary technical knowledge and tools.

- Understanding the warranty implications of DIY repairs.

Cost Breakdown by Vehicle Type

The cost of turbocharger repair or replacement varies significantly by vehicle type, with luxury and high-performance vehicles typically incurring higher costs.

| Vehicle Type | Average Repair/Replacement Cost |

|---|---|

| Compact Cars | $500-$1,500 |

| Luxury Vehicles | $1,500-$3,500 |

| High-Performance Vehicles | $2,000-$5,000 |

Warranty Considerations

Understanding the warranty considerations is vital. OEM parts usually come with a warranty, while aftermarket parts may or may not. Rebuilt turbochargers often have a limited warranty.

Making an informed decision on turbocharger repair or replacement requires balancing immediate costs with long-term reliability and performance. By considering the factors outlined above, vehicle owners can navigate this complex process more effectively.

Conclusion

The comprehension of turbo failure symptoms is paramount for averting and rectifying turbocharger malfunctions. Identifying indicators such as diminished power output, copious exhaust smoke, and anomalous sounds empowers vehicle proprietors to undertake preventive measures. Adherence to routine turbocharger upkeep, encompassing timely lubrication replenishment and filter substitution, is instrumental in prolonging the operational life of turbocharged engines.

In the event of malfunctions, an awareness of available turbo repair alternatives empowers vehicle owners to make well-informed choices. The decision between turbocharger rebuilding or replacement necessitates consideration of several factors, including financial outlay, the choice between OEM and aftermarket components, and warranty considerations. For a comprehensive exploration of turbocharger failure diagnosis and mitigation, refer to Turbochargers Plus, a repository of expert knowledge and guidance on turbocharger maintenance and repair.

FAQ

What are the common symptoms of a failing turbocharger?

Symptoms indicative of a failing turbocharger include a noticeable diminution in power and acceleration, alongside an increase in exhaust smoke. Distinctive noises such as whistling, whining, rattling, or grinding sounds emanating from the turbocharger are also common. Dashboard warning lights, oil leaks, and excessive oil consumption further signal potential issues.

How do I diagnose a failing turbocharger?

Diagnosing a failing turbocharger necessitates a combination of visual inspection techniques, performance testing methodologies, and the application of diagnostic tools and computer analysis. It is crucial to recognize the necessity for professional diagnosis at times.

What causes turbocharger damage?

Turbocharger damage is often attributed to oil-related maladies, including the use of suboptimal oil and inadequate lubrication. Foreign object damage and contamination, as well as carbon and soot buildup, contribute to its deterioration. Excessive heat and pressure, alongside manufacturing and design defects, also play significant roles.

Can I repair a turbocharger myself?

While certain repairs may be feasible, the scope for DIY intervention is generally limited. Often, professional assistance is indispensable. The decision to rebuild or replace a turbocharger must be made with due consideration, weighing the merits of OEM versus aftermarket options.

How much does it cost to repair or replace a turbocharger?

The financial burden of repairing or replacing a turbocharger is influenced by several factors, including the vehicle’s make and model. Costs encompass parts, labor, and the choice between rebuilding or replacement. Warranty considerations also play a pivotal role in determining the overall expense.

What is the difference between rebuilding and replacing a turbocharger?

Rebuilding a turbocharger entails the repair or replacement of damaged components, whereas replacement involves the installation of a new unit. The decision between these alternatives hinges on the severity of the damage and other pertinent factors.

How can I prevent turbocharger failure?

Preventive measures against turbocharger failure include diligent maintenance, such as regular oil changes with high-quality lubricants. Vigilance for signs of impending failure and prompt resolution of any issues are also essential.

What are the benefits of a turbocharged engine?

Turbocharged engines offer several advantages, including enhanced power and efficiency, improved fuel economy under specific conditions, and superior overall performance.